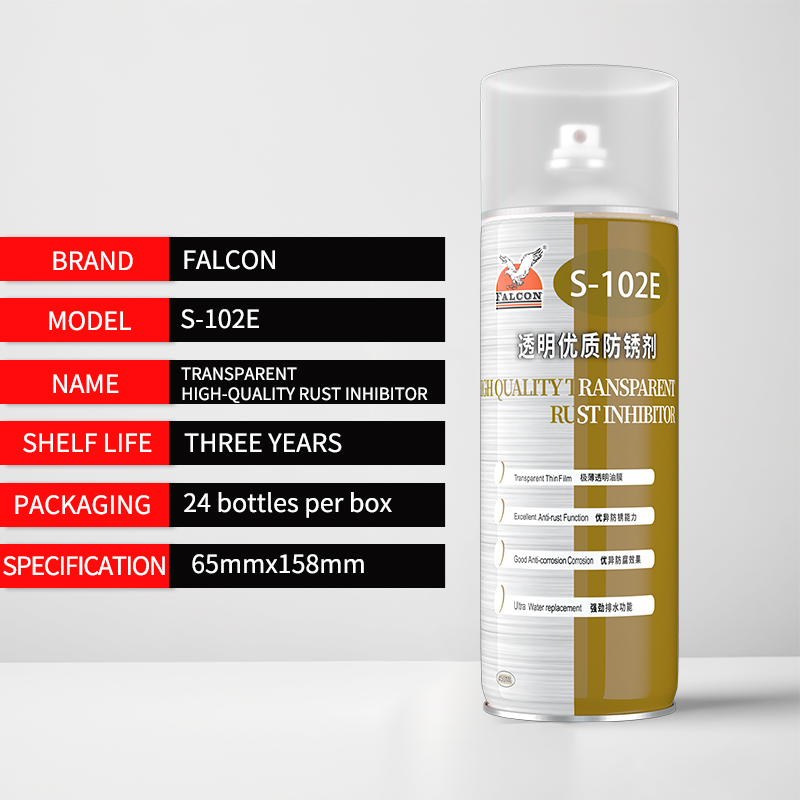

Falcon antirust agent S-102E is a gasified antirust agent, which is carefully prepared by carefully selecting refined base oil and high-quality antirust agent, and is sprayed on the surface of workpiece to quickly form a transparent antirust film. This antirust agent does not stick to the mold, and the antirust period is about 1 ~ 3 months.

● Low rust-proof effect, high cost performance, not easy to sag on the workpiece.

● Anti-rust oil film is easy to remove, reducing the use of cleaning agents.

● Excellent human sweat replacement.

● Environmental protection products, in line with EU RoHS environmental protection directives.

● Non-toxic and harmless to human body; The smell is low and easy for operators to accept.

● The tank body bears high pressure and is safe to use, effectively eliminating potential safety hazards.

● Before spraying antirust agent, the surface of the sprayed object should be cleaned with cleaning agent and the surface should be dried. After cleaning, it can be dried by filtered dry compressed air or dried by a dryer at 120-170℃.

● Before use, please shake the can body up and down properly to shake the product evenly, so as to make the sprayed mist more uniform.

● When spraying, press the nozzle so that the nozzle is about 30cm away from the object and spray vertically. Depending on the thickness of the oil film, move it evenly or spray it to the surface of the workpiece for many times to form an antirust film.

● After spraying, place the workpiece in a ventilated and dry environment for 24 hours.

test item | test method | unit | typical data |

Copper corrosion | ASTM D130 | / | 1a |

Rust-proof salt spray test | ASTM B117 | h | ﹥2 |

Internal pressure | GB/T14449 | MPa | ≤0.8 |

Ejection rate | GB/T14449 | % | ≥98 |

The above data are typical and do not represent product indicators. The above information is subject to change without notice due to the update of additives. This data is for reference only.